THE VACUWORX ADVANTAGE starts with a commitment to safety. All heavy-duty Vacuworx Vacuum Lifting Systems feature wireless remote operation and 360° rotation to position materials without the need for tag line operators on the ground. These features offer a safer alternative to using hooks, slings or chains and help keep personnel out of harm’s way.

Vacuworx Lifting Systems also increase productivity and benefit your bottom line. Vacuum lifting allows faster load and unload cycles with less downtime than conventional methods since there are no slings and chains to hook and unhook, while the need for fewer ground personnel reduces the risk of accidents and lowers payroll and insurance costs. ROI is often realized in 6 months or less through reduced labor costs, bonus awards and the ability to take on more projects.

Benefits of vacuum lifting vs. conventional methods

- Eliminates the need for unsafe and time-consuming lifting mechanisms such as hooks, slings or chains

- Less downtime between lifts

- No need for employees to climb on trailers to attach slings or chains

- Can lift material without displacing adjacent pieces

- Creates a powerful positive engagement of the load (hooks, slings and chains can shift or come loose, endangering employees)

- Reduces or eliminates need for tag line operators on the ground

- Vacuum lifting systems are able to go where people should not be

- Eliminates the need for costly cribbing or spacers for pipe or plate

- Visual and audio alarms indicate unsafe lifting environments

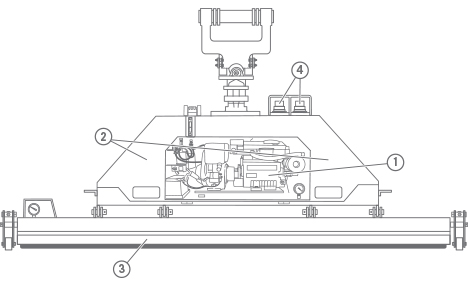

4 principal components

- Vacuum pump

- Driven by a self-contained engine or hydraulically powered by the host machine (electric models are also available)

- Vacuum reservoir and valve

- Provides vacuum in the event of a power failure

- Vacuum pad(s)

- Pipe, flat and specialty pads available

- Easily interchangeable to lift different materials

- Visible and audible vacuum alerts

How vacuum lifting works

- The vacuum pump maintains a constant vacuum in the pressure reservoir

- When activated, the system pulls a vacuum between the pad and object to be lifted, providing a powerful positive seal

- Pad seal is used on the vacuum pad to cover the material to be lifted and create the necessary suction

- Vacuum seal holds until operator activates the release (even in the event of a power failure)

- Patent pending Tough Seal™ is formulated to withstand rugged jobsite conditions and extreme temperatures

- Enhanced UV protection reduces damaging effects of sunlight

- 360° seamless outer skin resists abrasions and repels destructive oils and moisture

- Engineered for temperatures up to 215°F and as low as -40°F

- Operated by electronic wireless remote control transmitter with matched receiver

- Multiple lifters can work side by side without interference